Two-wheeler

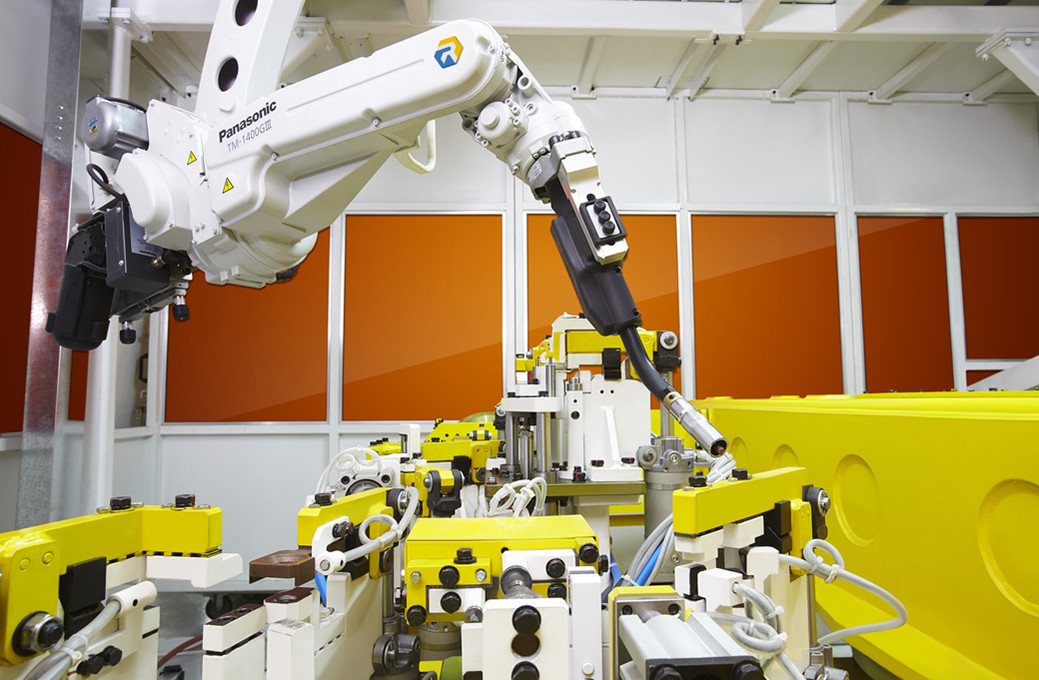

By applying Risong Technology in the production lines of motorcycles and electric vehicles, the robotic welding system, welding fixtures and checking fixtures are integrated to weld and assemble the frame, fuel tank and muffler, and 100% full-position and full-angle welding is realized by using full-automatic polishing and grinding technology, full-automatic robotic seam welding, automatic flame brazing, and low spatter welding technology, which ensures less deformation and no need for manual correction, thus significantly reducing the cost. During the welding process, the acquisition, feedback and optimization of welding technical parameters can be achieved. The production line designed and built by Risong for a customer involves an independently designed three-axis large slewing diameter mechanism, with robots applied in the welding of motorcycle and electric vehicle frames, which improves the stability, accuracy and welding quality of the welding process. In addition, Risong applies the remelting process to the welding of high-strength and lightweight materials such as aluminum alloys, which is leading in the industry.