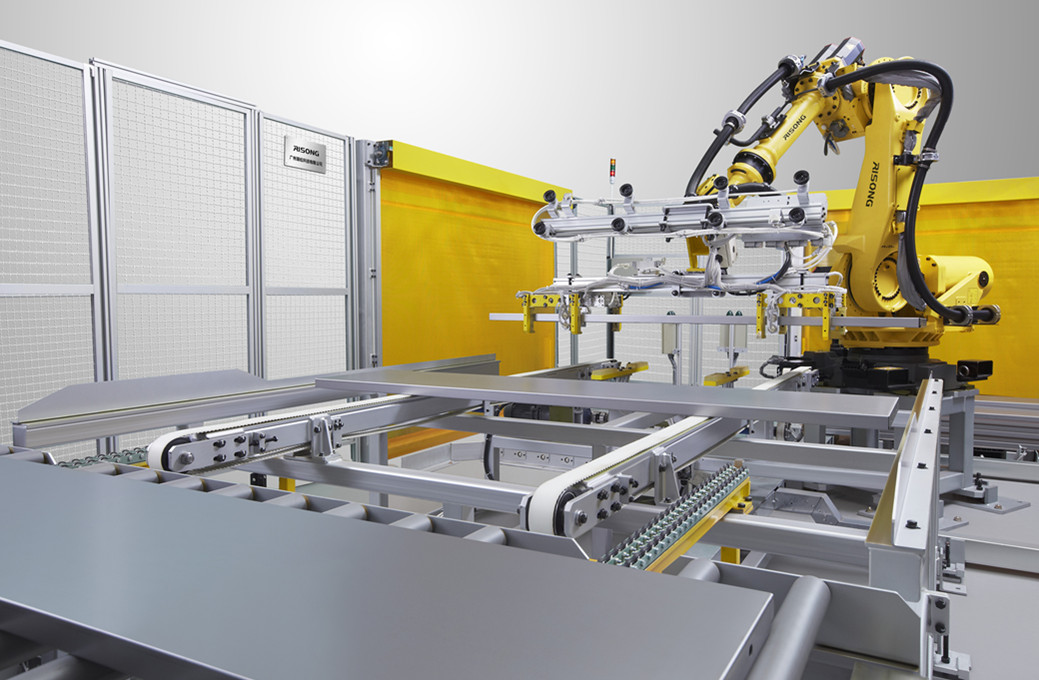

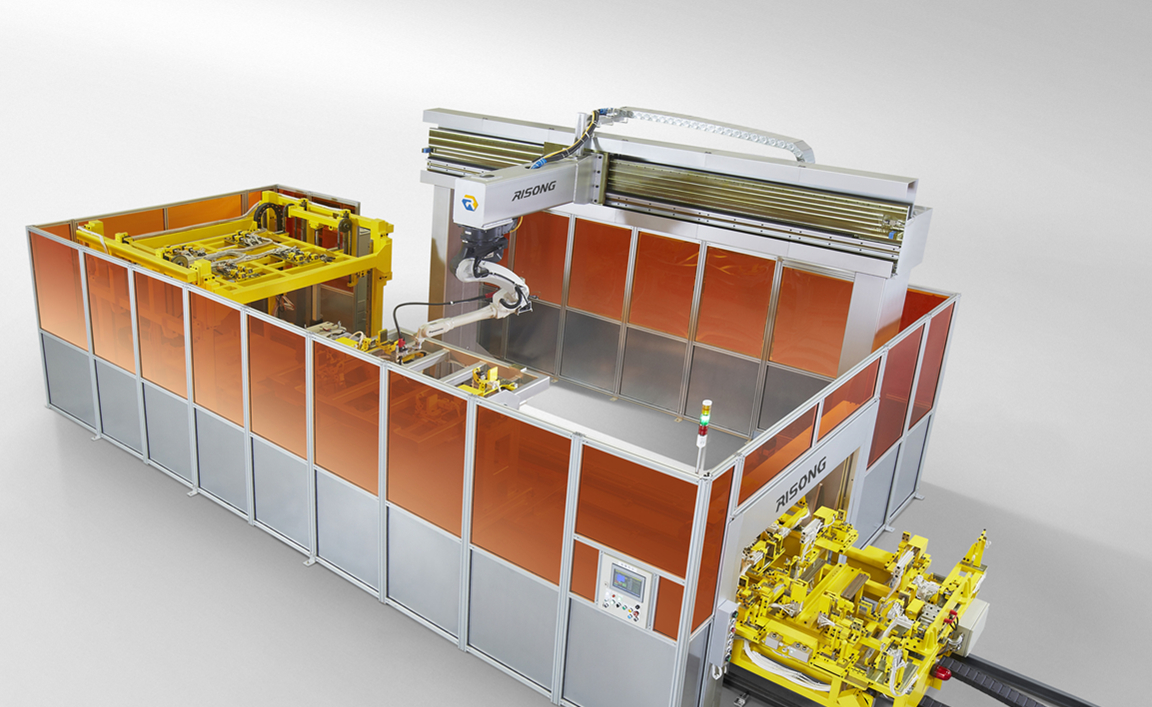

Risong's elevator manufacturing automation solutions provide automatic production lines for the elevator manufacturing industry, such as production lines for wallboards, roofs, floors, underframes, door jamb pillars, door panels, door jambs, door heads, and pillars, involving the application of 17 categories of elevator components. In total, Risong has delivered more than 100 sets of equipment to customers in the industry, and owns 31 related patents in the elevator industry. It maintains a professional design team with mature experience in the elevator industry.

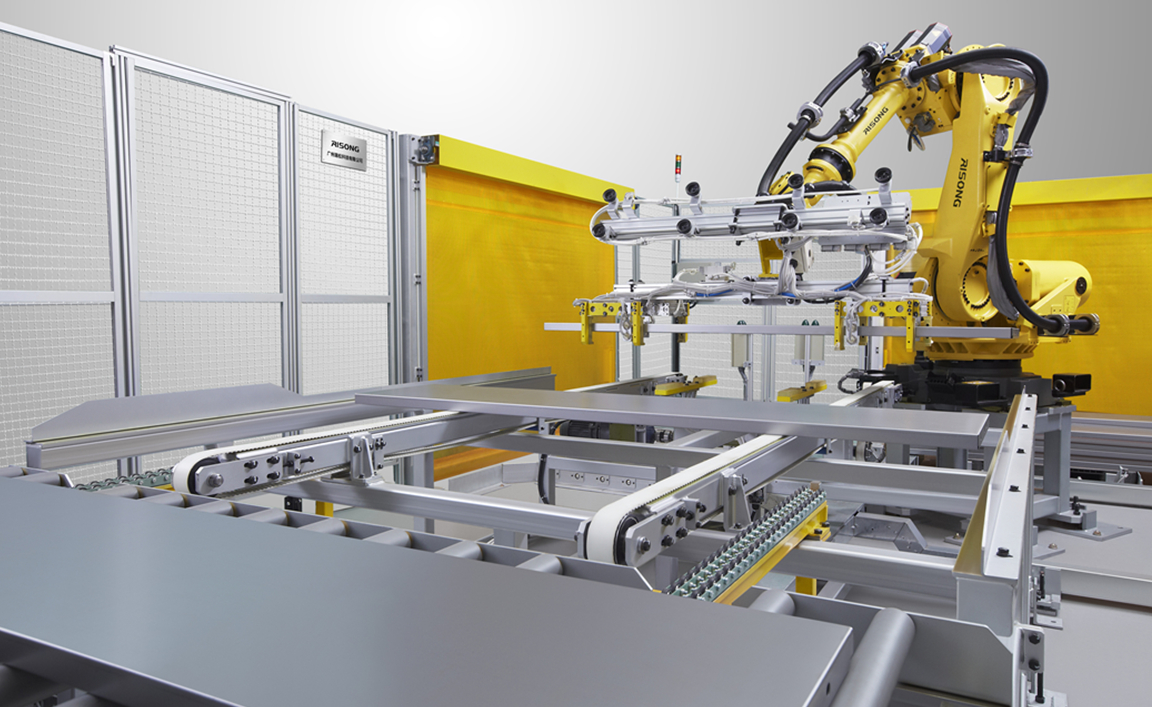

Risong has mastered key technologies such as automatic conveying and locating, automatic riveting, automatic loading, automatic grabbing of workpieces, automatic detection of workpiece specifications and positions, and automatic loading and packaging of paper in the elevator production process. From sheet metal to product packaging, the whole elevator laminate production process has become unmanned, significantly improving production efficiency and product quality.

Specifically, according to the production process features of elevator workpieces, Risong has developed new riveting processes related to blind riveting, pull riveting, rivetless riveting and self-piercing riveting, etc., optimized the existing processes of customers, and applied the full-automatic gluing system to elevator production, realizing the automation of gluing. Risong adopts modular design, such as painting components, screwing components, arc welding components, and spot welding components, for customers' choice of corresponding technical modules according to different process requirements, which allows high openness and combination of modules to build different elevator production systems catering to specific requirements. Risong is one of the first enterprises in the elevator industry to transform and upgrade the traditional production line with robots, reflecting its overall solution ability and its strength in continuous technology development and innovation.